Well Control Incident with Complications While Attempting to Cure Total Losses

A well control incident took place while preparing to sever the drill string above the plugged BHA.

While preparing to severe pipe, the well flowed and was shut in. Bullheading was attempted but failed as pressure was kept low for hole integrity concerns. Pipe was severed above BHA, but circulation was still not possible. Additional LCM pills were pumped, followed by cement. Circulation regained. During Drillers Method circulation, high gas readings and oil contaminated mud seen and shakers. Circulation was stopped. No returns when attempting to restart circulation. Decision made to bullhead without concern for open hole. Well killed and cement plugs pumped. Open hole abandoned.

IOGP Wells Expert Committee/Well Control Incident Subcommittee believes that this incident description contains sufficient lessons to be shared with the industry. We further encourage the recipients of this mail to share it further within their organization.

Drilling 8 1/2" reservoir section using Managed Pressure Drilling, with hydrostatically underbalanced mud. Water zone with high pressure exposed in start of the section, oil reservoir with slightly lower pressure exposed further down. Two severe loss incidents experienced while drilling, reducing the drilling window to 0.3 ppg.

Close to planned TD of the well, third severe loss zone encountered. LCM treatment unsuccessful. Decided to pump "total loss" LCM pill; underdisplaced pill and left BHA on bottom due to concerns with provoking a leak in MPD annular if stripping above the pill. Attempted circulation and observed string plugged. Mobilized severing equipment, meanwhile decided to shut in well to stabilize losses and preserve mud; closing the BOP removed the MPD back pressure, reducing the bottom hole pressure. Loss rate decreasing and levelling out while waiting for equipment.

While preparing to sever string above BHA, observed gain and shut in well again. Attempted cautious bullheading, limited by integrity of previous loss zone, unsuccessful. Severed string above BHA and attempted Driller's method, unable to establish returns.

Pumped LCM and cement and achieved formation integrity for circulating. 2nd attempt of Driller's method stopped due to early arrival of high gas readings at shakers, and heavily oil-contaminated mud. No returns when re-starting circulation. Decided to bullhead well without constraints towards formation integrity, loss of section accepted. Placed cement plugs in open hole.

What Went Wrong?:

- Higher pressure than predicted in water zone early in 8 1/2" section. Several loss incidents due to lower formation strength than predicted - drilling window severely reduced.

- Well control response delayed due to plugged string with LCM. While waiting for severing equipment with well shut in on BOP, MPD back pressure was removed and thus bottom hole pressure reduced, allowing x-flow from high pressured water zone into the loss zone at TD. Hydrostatic column weight was thus reduced and influx from oil zone allowed. Actual bottom hole pressure increasingly uncertain due to mixture of fluids.

- After communication through drillstring achieved by severing, Driller's method attempts with unstable pressures due to deteriorated mud allowed additional influx in well.

Corrective Actions and Recommendations:

- Ensure to overdisplace a "total loss" LCM pill and flush string afterwards.

- Pressure limit on first bullheading attempt was too low, assuming uniform mud column all the way; actual bottom hole pressure in the annulus was likely lower, due to lighter fluids (water and oil) having entered the wellbore.

- Well control options constrained by attempts to save the section for subsequent wireline logging objective.

- Closing the BOP in a loss situation shall be thoroughly evaluated as it may cause underbalance in the well.

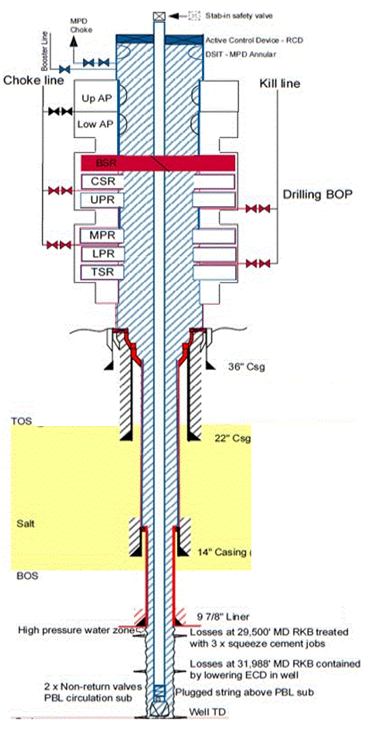

Figure 1: Well barrier schematic at time of incident

Well barrier schematic illustrating the barrier elements during an MPD operation. Note: BSR was not closed during the incident, it is only shown here as closing the secondary barrier envelope.

safety alert number: 335

IOGP Well Control Incident Lesson Sharing http://safetyzone.iogp.org/

Disclaimer

Whilst every effort has been made to ensure the accuracy of the information contained in this publication, neither the IOGP nor any of its members past present or future warrants its accuracy or will, regardless of its or their negligence, assume liability for any foreseeable or unforeseeable use made thereof, which liability is hereby excluded. Consequently, such use is at the recipient's own risk on the basis that any use by the recipient constitutes agreement to the terms of this disclaimer. The recipient is obliged to inform any subsequent recipient of such terms.

This document may provide guidance supplemental to the requirements of local legislation. Nothing herein, however, is intended to replace, amend, supersede or otherwise depart from such requirements. In the event of any conflict or contradiction between the provisions of this document and local legislation, applicable laws shall prevail.