|

|

<<< Back to Results

| ||

|

Jacket levelling tool assembly link plate and pin failure |

||

Country: QATAR - Middle East | ||

Location: OFFSHORE | ||

Incident Date: 14 December 2021 Time: --- | ||

Type of Activity: Construction, commissioning, decommissioning | ||

Cause: Dropped objects | ||

Function: Construction | ||

What happened?:

A jacket level survey was ongoing, using a levelling tool installed on the top of the jacket pile and connected with grommets and shackles to the jacket legs on both sides. Pins of the right assembly slipped out from their position causing the grommet, right side link plate and lower pin to fall down. As a result of the event, the grommet remained on the scaffold being connected to the jacket leg, and the link plate with the pin (weight approximately 600kg) fell into the sea and landed on the jacket mud mat. The area around the levelling tool was restricted, with access to workers as per JSA control measures, in order to not have any personnel in the line of fire (LOF) during this activity and further level survey. | ||

What Went Wrong?:

| ||

Corrective Actions and Recommendations:

| ||

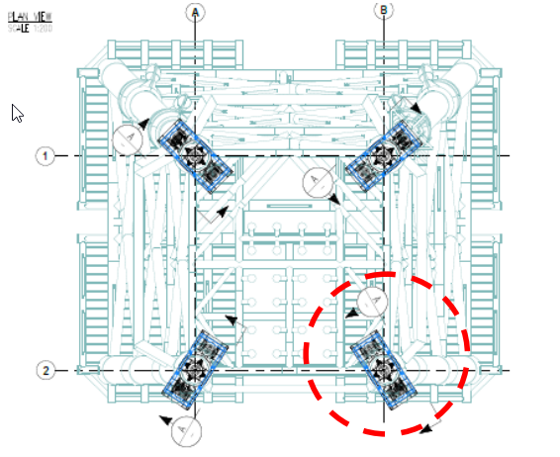

Figure 1: Jacket top view with levelling tool position indication

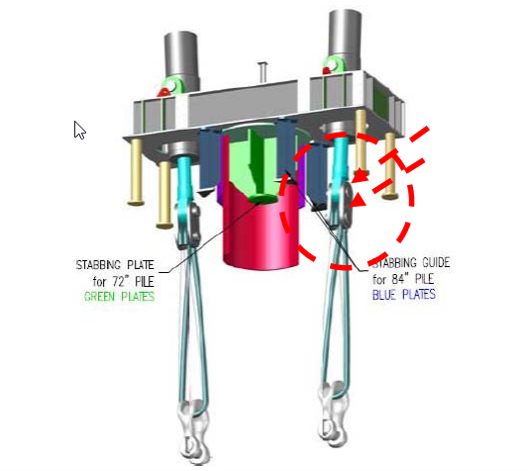

Figure 2: Side view of levelling tool position

Figure 3: Levelling tool and affected pin assembly

Figure 4: Levelling tool after the event  | ||

Safety Alert number: 342

| ||

Disclaimer

Whilst every effort has been made to ensure the accuracy of the information contained in this publication, neither the IOGP nor any of its members past present or future warrants its accuracy or will, regardless of its or their negligence, assume liability for any foreseeable or unforeseeable use made thereof, which liability is hereby excluded. Consequently, such use is at the recipient's own risk on the basis that any use by the recipient constitutes agreement to the terms of this disclaimer. The recipient is obliged to inform any subsequent recipient of such terms. | ||