|

|

|

Incorrect Pressure Gauge on High Pressure Supply Line

|

Country: UK - Europe |

Location: --- |

Incident Date: 3 September 2015 Time: 09:00 |

Type of Activity: Maintenance, inspection, testing |

Cause: Pressure release |

Function: Production |

|

What happened?:

When re-commissioning a Steam Turbine following maintenance, a small steam leak was observed from a pressure gauge located on the high pressure steam supply. The pressure gauge was rated to one Bar(g) and the safety seal failed when it was exposed to 55

Bar(g) steam during re-commissioning. The pressure gauge in question was brand new and had been fitted during the recent maintenance period.

|

What Went Wrong?:

- Operations inspected the pressure gauge and found it to be a 0-100% gauge, where a 0-100 Bar pressure gauge should have been installed.

- The 0-100% gauge had been ordered in error for a prior boiler shutdown and had been subsequently stored in the utilities equipment room, rather than returned to the warehouse for disposal.

- Technicians had established a culture of storing some small items in equipment rooms to allow easy access for small maintenance tasks.

- On the day of installation, the 0-100% gauge was mistaken for a 0-100 Bar pressure gauge (due to the near identical appearance) and was taken from the utilities equipment room and installed on the steam turbine high pressure steam supply line. A human error

mode of “miss-perception” was recorded following a Human Factors investigation.

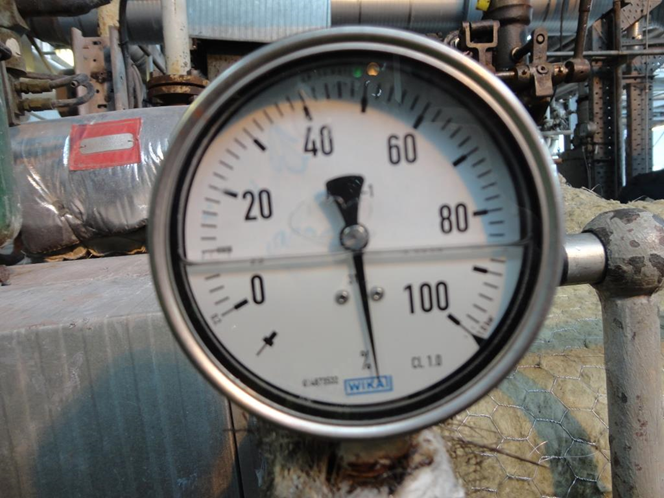

Figure 1 – Correct pressure gauge (Bar)

Figure 2 – Incorrect Pressure Gauge (%)

|

Corrective Actions and Recommendations:

- Check all stores stock to ensure that all pressure gauges are stored in the correct place and in the correct boxes.

- Ensure that all un-used equipment is returned to the place of issue at the end of each day. This ensures that only the correct equipment for a specific work order can be withdrawn.

- Ensure that all pressure gauges are function checked and fit for purpose before installation.

- Review stores stock items and material numbers to establish those that are no longer used or required. Block all numbers that are not required in to prevent re-ordering by accident.

- For legacy assets, review and rationalize all local pressure gauges across each facility with a view to removing those that are no longer used or required.

|

|

|

Safety Alert number: 284

IOGP Safety Alerts http://safetyzone.iogp.org/ |

Disclaimer

Whilst every effort has been made to ensure the accuracy of the information contained in this publication, neither the IOGP nor any of its members past present or future warrants its accuracy or will, regardless of its or their negligence, assume liability for any foreseeable or unforeseeable use made thereof, which liability is hereby excluded. Consequently, such use is at the recipient's own risk on the basis that any use by the recipient constitutes agreement to the terms of this disclaimer. The recipient is obliged to inform any subsequent recipient of such terms.

This document may provide guidance supplemental to the requirements of local legislation. Nothing herein, however, is intended to replace, amend, supersede or otherwise depart from such requirements. In the event of any conflict or contradiction between the provisions of this document and local legislation, applicable laws shall prevail.

|