Leaking flange between coil tubing BOP and stripper assembly

IOGP Well Control Incident Lesson Sharing #23-8

During a coil tubing clean out run a leak developed at a flange between the quad BOP and stripper assembly. The leak was initially stopped following the appropriate protocol however it continued to occur resulting in the requirement to bullhead the well to minimize the risk of gas a surface. The coil tubing was successfully recovered from the well and a tensioning system was installed to prevent side loading and future leaks.

The Wells Expert Committee/Well Control Incident Subcommittee believes that this incident description contains sufficient lessons to be shared with the industry. We further encourage the recipients of this lesson sharing to share it further within their organization.

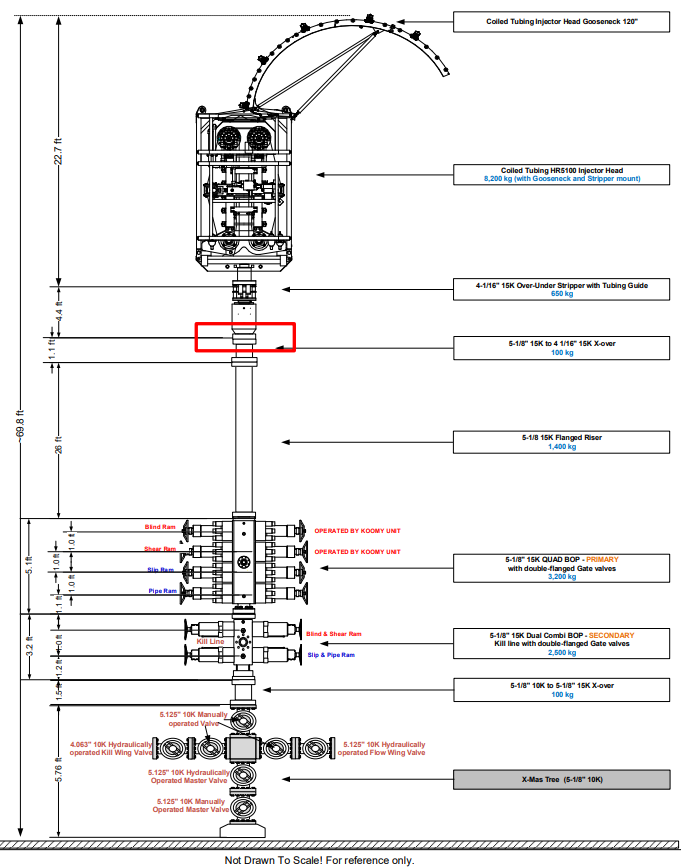

Following a multi-stage fracture completion, a post-frac clean-out run with coil tubing was performed. Prior to running in the hole all connections had been torqued to the recommended value using hydraulic wrench and pressure tested before the run. When the coil tubing clean out assembly was at 15,900ft, a fluid leak was observed at a flange between the 4-1/16" stripper and 4-1/16" x 5-1/8" crossover above the quad BOP (Refer to stack up schematic). Operations were stopped and an Emergency Check List (ECL) protocol performed: the quad BOP was closed, pressure was bled-off and the flange tightened. The leak stopped. Operations resumed and the clean-out run was completed at 16,049 ft.

While initiating pulling out of the hole, a fluid leak was reported from the same flange. Operations were stopped and a further ECL protocol was performed. The leak stopped and pulling out of hole resumed. At 15,844 ft, the flange was again observed to be leaking and a further ECL protocol was performed, but a limited leak remained.

The situation was assessed and discussed with town, and the decision was made to pull out of hole to surface. A further stop was implemented at 13,000ft as some gas was observed at the leaking flange. The well was circulated to remove the gas. Pulling out of hole was resumed until the fluid leak was observed to be increasing at 679ft. A ECL protocol was performed and the well bullheaded through the kill line to minimize the risk of gas at surface. Pulling out of hole resumed and the coil tubing was recovered back to surface.

Figure 1: Schematic of stack up

What Went Wrong?:

Suspected miss-alignment of the assembly generating fatigue and incorrect repartition of the load on the seals resulting in the leak.

Corrective Actions and Recommendations:

- Contingency plans were in place, such as emergency checklist protocol, and successfully implemented.

- It was concluded that the full stack up was not sufficiently supported and the side load constraints initiated by the injector head during the run jeopardized the load repartition on the ring gasket.

- A tensioning system was installed to mitigate any side-tension on the stack up. No more leaks were observed.

safety alert number: 357

IOGP Well Control Incident Lesson Sharing http://safetyzone.iogp.org/

Disclaimer

Whilst every effort has been made to ensure the accuracy of the information contained in this publication, neither the IOGP nor any of its members past present or future warrants its accuracy or will, regardless of its or their negligence, assume liability for any foreseeable or unforeseeable use made thereof, which liability is hereby excluded. Consequently, such use is at the recipient's own risk on the basis that any use by the recipient constitutes agreement to the terms of this disclaimer. The recipient is obliged to inform any subsequent recipient of such terms.

This document may provide guidance supplemental to the requirements of local legislation. Nothing herein, however, is intended to replace, amend, supersede or otherwise depart from such requirements. In the event of any conflict or contradiction between the provisions of this document and local legislation, applicable laws shall prevail.