Surface gas release after cutting production casing string

IOGP Well Control Incident Lesson Sharing #23-5

During slot recovery operations on a platform well, a 0.9 bbl gain was observed from the B-annulus while performing a flow-check after cutting the 9-5/8” casing. The flow-check was extended to confirm static well conditions and the gain was interpreted as fluid u-tubing. Circulation was then initiated, resulting in a gas release at surface and general platform alarm. The well was successfully shut-in on the Annular. Further attempts to circulate the well via choke manifold and MGS were abandoned due to high gas levels persisting after the MGS. A well test / bleed down package was used to finally kill the well safely.

The Wells Expert Committee/Well Control Incident Subcommittee believes that this incident description contains sufficient lessons to be shared with the industry. We further encourage the recipients of this lesson sharing to share it further within their organization.

Event occurred during slot recovery of a platform well originally drilled & completed in 1995. Gas released from the B-annulus (13 3/8" x 9 5/8" annulus) following cutting of the 9 5/8" casing string. Initial flow check performed post cut recorded initial 0.9bbls gain and thereafter stable well response (assumed/anticipated in operations as fluid u-tubing between the different fluid hydrostatics present within the well bore). Note: seal assembly removed earlier under closed annular preventer with no indication of flow from the annulus. The well has a complex history and the platform has had multiple changes of operatorship over the last 20 years.

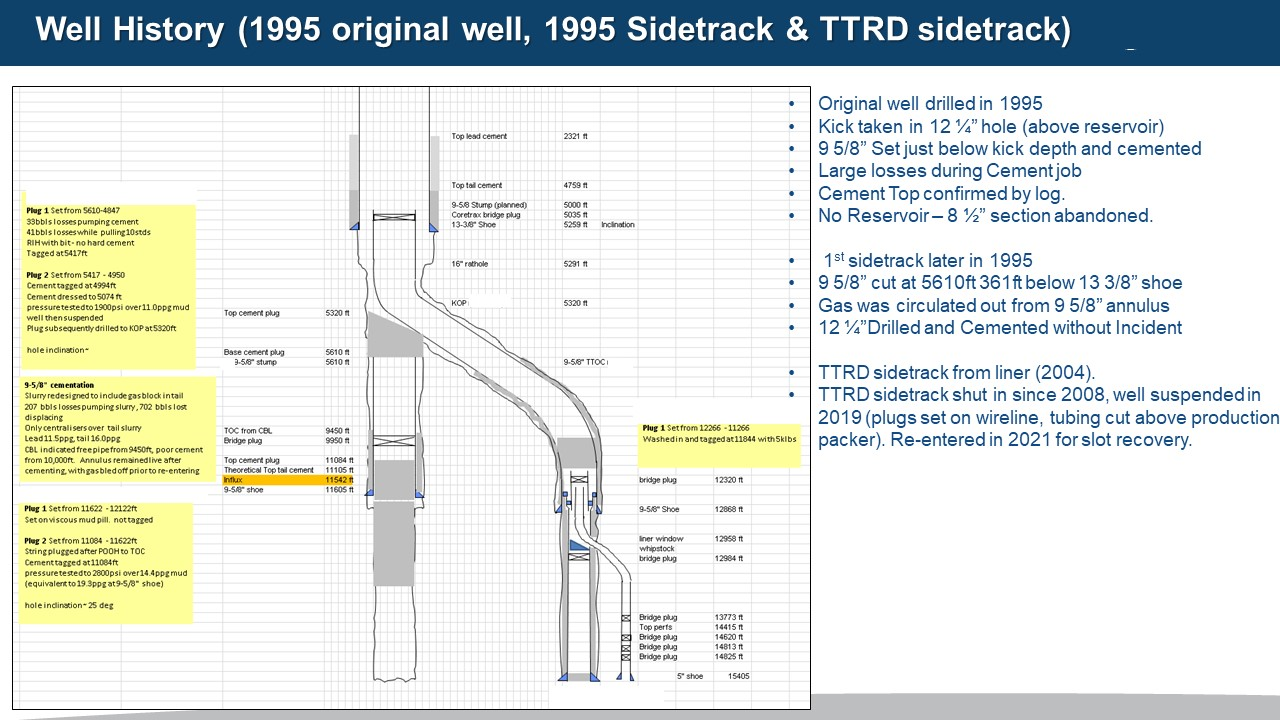

Original spud date January 1995. Kick taken whilst drilling 12 1/4" interval. Well killed and 9 5/8" run and cemented. No reservoir encountered in 8 1/2" section. Well P&A and sidetracked later in 1995, completed as a production well. Identified as TTRD candidate and sidetracked through liner in 2004. Well operated until 2008 and shut in. Well suspended via wireline intervention in 2019. Slot recovery commenced in April 2021.

What Went Wrong?:

Presence of hydrocarbon (reservoir crude & associated gas) in B-annulus. Mechanism by which this fluid entered the B-annulus is unknown however potential exists for juxtaposition of overburden formation against reservoir on the North side of the field through faulting. This may lead to a hydrocarbon charge in the overburden and be an explanation for the 12 1/4" section kick experienced in the initial well bore.

No demonstrable evidence of communication to the B annulus from annuli pressure data, and no record of fluids being sampled from the B-annulus over the life of the well & sidetracks.

Corrective Actions and Recommendations:

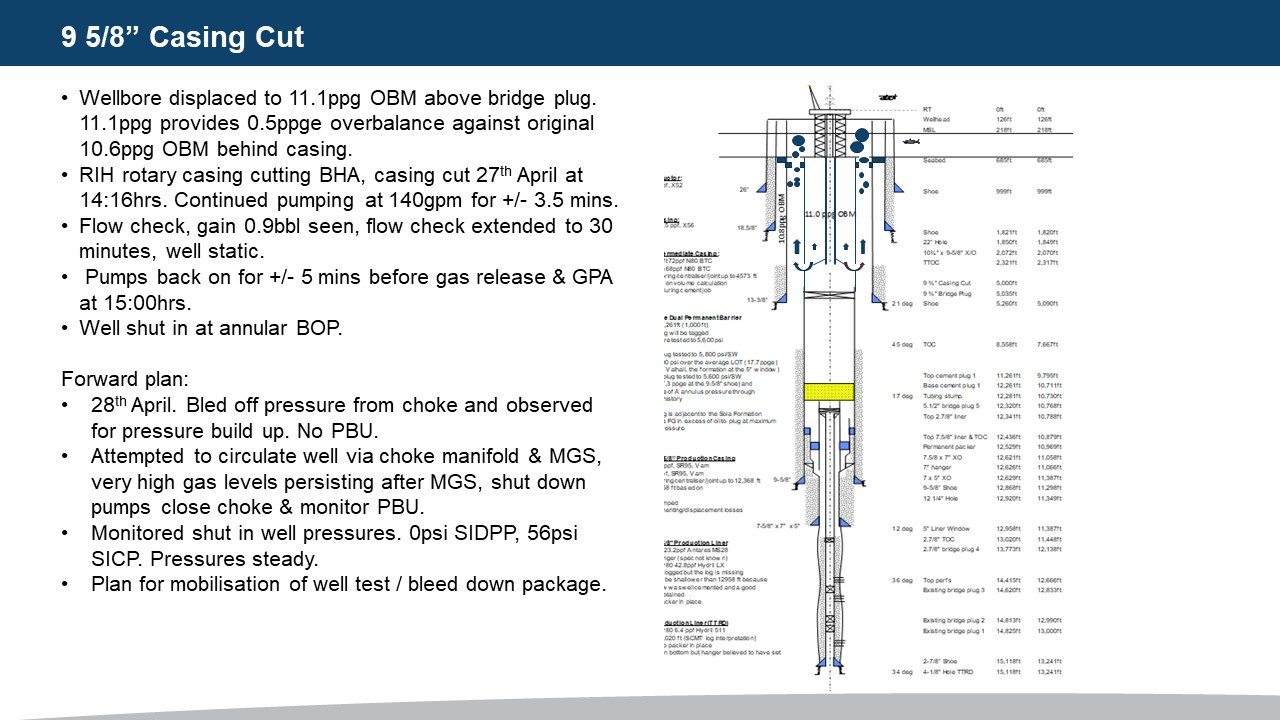

Figure 1: Casing Cut schematic

Well status during 9 5/8" casing cut 27th April 2021

Figure 2: Slot History

Schematic illustration of 1995 original well, 1995 sidetrack and subsequent TTRD sidetrack.

safety alert number: 351

IOGP Well Control Incident Lesson Sharing http://safetyzone.iogp.org/

Disclaimer

Whilst every effort has been made to ensure the accuracy of the information contained in this publication, neither the IOGP nor any of its members past present or future warrants its accuracy or will, regardless of its or their negligence, assume liability for any foreseeable or unforeseeable use made thereof, which liability is hereby excluded. Consequently, such use is at the recipient's own risk on the basis that any use by the recipient constitutes agreement to the terms of this disclaimer. The recipient is obliged to inform any subsequent recipient of such terms.

This document may provide guidance supplemental to the requirements of local legislation. Nothing herein, however, is intended to replace, amend, supersede or otherwise depart from such requirements. In the event of any conflict or contradiction between the provisions of this document and local legislation, applicable laws shall prevail.