Influx observed while drilling out lower cement plug on well being abandoned

IOGP Well Control Incident Lesson Sharing #23-3

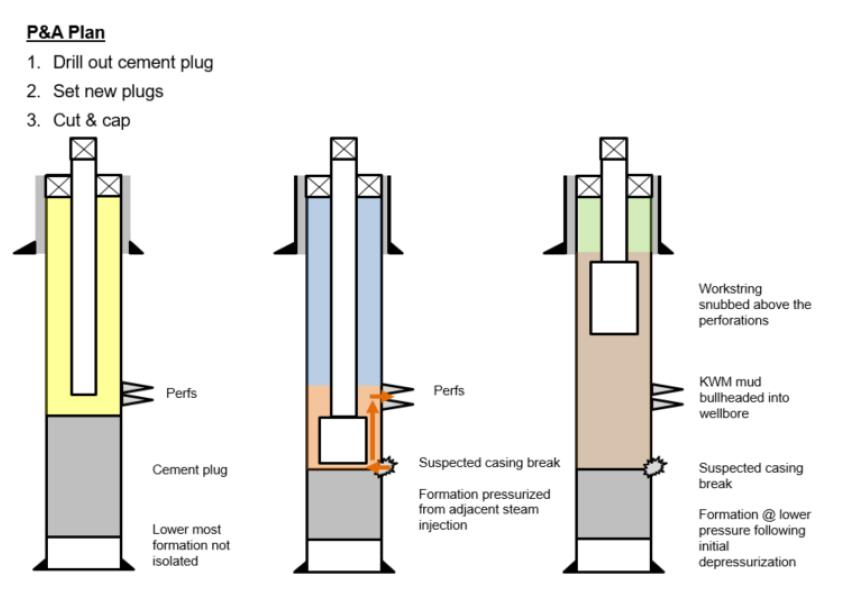

Plug and abandon operations were initiated on vertical well using a service rig. After the BOP was rigged up on the wellhead and pressure tested, the completion was pulled. A drilling assembly was then RIH to drill out an existing cement plug that was in place to isolate a lower zone. While drilling the lower abandonment cement plug, an influx was detected at surface. Once the influx was identified, the well was shut-in successfully on the BOPís. This lesson sharing shows how important is to perform risk assessments of potential pressure sources from offset wells while performing infill well servicing / abandonment operations. See Figure #1 below for additional details.

The Wells Expert Committee/Well Control Incident Subcommittee believes that this incident description contains sufficient lessons to be shared with the industry. We further encourage the recipients of this lesson sharing to share it further within their organization.

Vertical gas producer with lateral offset production from deeper formation. Deeper formation was isolated on the incident well with a cement plug, shallower gas zone open above with perforations. Plug and abandon (P&A) operations initiated on the incident well: the completion was pulled from the well and a service rig was in the process of drilling out the cement plug (to fully isolate lower zone) when an influx was detected and the well shut-in. An attempt to kill the well via bullheading with overbalanced fluid was made but failed due to suspected underground flow from the deeper zone to the shallow (depleted) zone above. Offset steam-injection activities also identified as contributing to well kill complexity. Depressurization of lower zone from offset wells initiated, snubbing unit utilized to snub string above upper zone perforations and subsequently killed the well via bullheading. P&A completed post-depletion of lower zone.

What Went Wrong?:

- Communication - Offset production activities imparted high pressure to the lower zone during the P&A. Normal planning process, which makes affected work groups aware of such P&A activities did not make the affected work groups aware of the P&A resulting in the offset steam injection activity taking place simultaneous with the P&A operation.

- Risk Assessment/Pre-Job Planning - Lack of Hazard Recognition - proximity of the incident well to offset production activities was not identified by the existing risk screening process/procedure. The reservoir engineering team (who oversees steam injection activities) was not included in the planning process. Additionally, the nature of the well (thermal operation at shallow depth) was not recognized as posing a unique hazard for flow to surface (unrealized consequence).

Corrective Actions and Recommendations:

- Modify risk screening tool to flag operations where offset operations could create pressurized formations affecting work on a given well, require the identification of distance to an active thermal well, with a mechanism to trigger a formal technical review.

- Modify risk assessment tool to address that the previously utilized risk screening tools did not flag the planned operation as unique, nor have a mechanism to flag the unique hazard that exists for thermal operations at shallow depths, where a flow to surface event could develop.

- Involve reservoir team on all P&A operations.

- Include the potential for crossflow, and the potential for casing failure below the cement plug, to risk assessments for future P&A operations.

- Share the incident, contributing factors, and lessons learned within the company and externally to raise general awareness of the hazard.

- Coordinated response to resolve the incident and availability of technical support and response team mitigated impact of the event.

Figure 1: P&A plan and sequence of events

safety alert number: 349

IOGP Well Control Incident Lesson Sharing http://safetyzone.iogp.org/

Disclaimer

Whilst every effort has been made to ensure the accuracy of the information contained in this publication, neither the IOGP nor any of its members past present or future warrants its accuracy or will, regardless of its or their negligence, assume liability for any foreseeable or unforeseeable use made thereof, which liability is hereby excluded. Consequently, such use is at the recipient's own risk on the basis that any use by the recipient constitutes agreement to the terms of this disclaimer. The recipient is obliged to inform any subsequent recipient of such terms.

This document may provide guidance supplemental to the requirements of local legislation. Nothing herein, however, is intended to replace, amend, supersede or otherwise depart from such requirements. In the event of any conflict or contradiction between the provisions of this document and local legislation, applicable laws shall prevail.