Lack of management of change process, associated with late detection, caused considerable kick volume on regular completion operations

After finishing drilling and displacing completion fluid on to the well, due to a lapse of management of change process, the well became underbalanced when shutting off pumps. Since it was a routine operation, the operation team was not expecting an influx in such situation, leading to a late gain detection. This alert shows how important is to manage properly any changes that happen on a wellís plan and to be prepared for a well control incident, even when regular operations take place.

The Wells Expert Committee/Well Control Incident Subcommittee believes that this incident description contains sufficient lessons to be shared with the industry. We further encourage the recipients of this mail to share it further within their organization.

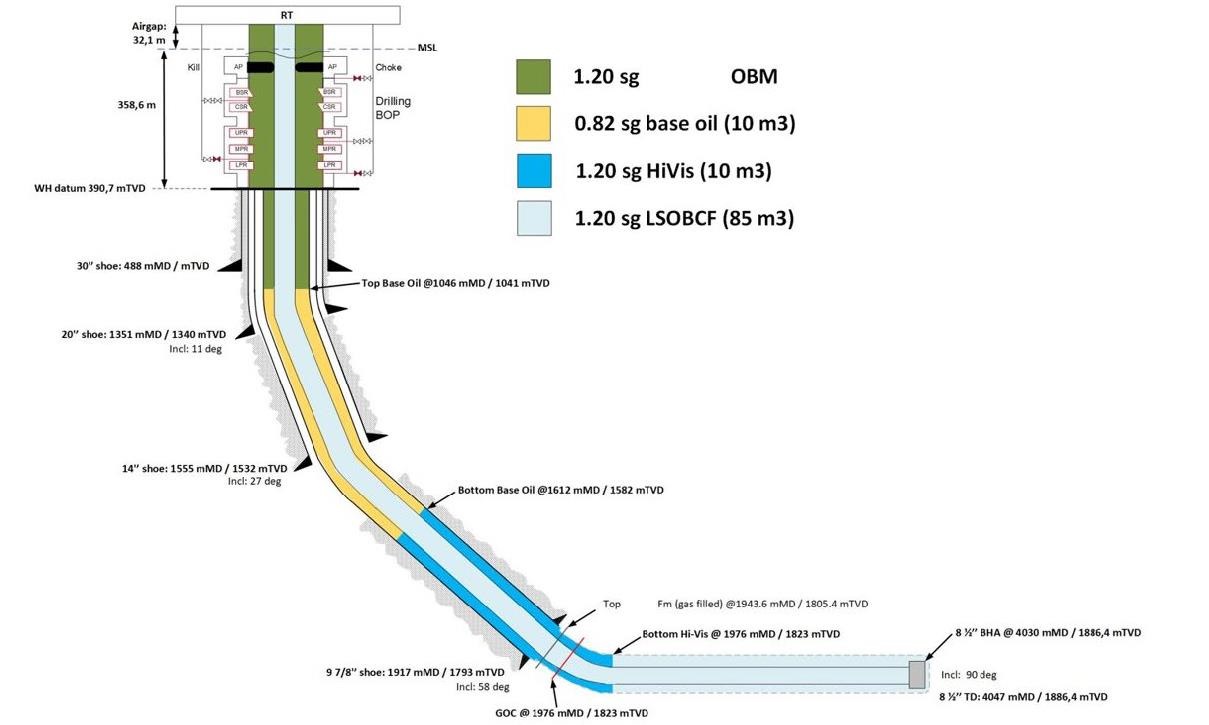

Drilled 8 1/2ď horizontal reservoir section to section TD at 4047 mMD with 1.20 sg OBM. The hole was circulated clean. Flow checked well on trip tank. Experienced seepage loss / static loss of 540 litre / hour with decreasing trends towards 280 litre / hour.

Plan to displace open hole section from 1.20 sg Oil Based Mud (OBM) to 1.20 sg Low Solids Oil Based Completion Fluid (LSOBCF), then pull into casing shoe and continue displacement of well to 1.20 sg LSOBCF.

Displaced open hole to LSOBCF by pumping a wash train ahead of the LSOBCF consisting of 10 cubic metres of 0.82 sg base oil, followed by 10 cubic metres of 1.20 sg hi-vis pill. Stopped pumping after having partially displaced open hole to LSOBCF. Parts of the wash train were still in the open hole section at the time that the pumps were stopped.

Flow checked well on full trip tank due to expectation of loss and plan for tripping out. Observed well flowing, explained by u-tube effect due to base oil in annulus (not calculated up front). Flowback gradually increased; trip tank needed to be emptied. After TT was emptied (2:15 minutes), an accelerated gain was observed. Shut in well on annular after another 2 minutes, total gain of 8.7 cubic metres.

In retrospect, wired drill pipe bottom hole pressure showed continuous drop of EMW from u-tube effect during flow check, to below expected pore pressure. The gas was circulated out of the well using drillerís method. The string and open hole in annulus were already filled with kill mud (1.20 sg LSOBCF), hence only one circulation required to kill the well.

What Went Wrong?:

- Base oil introduced in wash train late in offshore operational plan, without knowledge of leading personnel offshore and onshore.

- The well became underbalanced when shutting off the pumps.

- Late detection and acknowledgement of influx led to increased kick size, gain accelerating as trip tank was being emptied.

Corrective Actions and Recommendations:

- Management of change process did not work as intended.

- Lack of quality assurance of displacement plan, and precision in volumes.

- The wash train fluids were not specified with volumes and densities in the detailed operational procedure.

- Increase awareness of wired drill pipe data for early kick detection. The full potential was not utilized as no one reacted to the decreasing EMW during flow check.

- Lower threshold for shutting in well when in doubt; calculations indicate that gas was maximum 10 minutes away from entering riser.

- Distribute learning throughout the company. Detailed operational procedure to include displacement fluids with volumes and densities. QC of displacement plans.

- Clarify responsibilities and strengthen the Operational Barrier elements.

Figure 1: Well schematic at time of incident

Well schematic showing the position of various fluids in the well prior to flow check (in underbalance to pore pressure due to base oil in wash train)

safety alert number: 341

IOGP Well Control Incident Lesson Sharing http://safetyzone.iogp.org/

Disclaimer

Whilst every effort has been made to ensure the accuracy of the information contained in this publication, neither the IOGP nor any of its members past present or future warrants its accuracy or will, regardless of its or their negligence, assume liability for any foreseeable or unforeseeable use made thereof, which liability is hereby excluded. Consequently, such use is at the recipient's own risk on the basis that any use by the recipient constitutes agreement to the terms of this disclaimer. The recipient is obliged to inform any subsequent recipient of such terms.

This document may provide guidance supplemental to the requirements of local legislation. Nothing herein, however, is intended to replace, amend, supersede or otherwise depart from such requirements. In the event of any conflict or contradiction between the provisions of this document and local legislation, applicable laws shall prevail.