Uncontrolled flow during coiled tubing nitrogen lifting operation

During a coiled tubing nitrogen lifting operation, a 30 foot section of degraded coil was ejected followed by uncontrolled well flow. The well was shut-in after 11 minutes with coiled tubing pipe and blind rams. The investigation showed that the coiled tubing parted due to excessive corrosion caused by multiple inhibition scenarios which were not identified in the pre-job planning.

The IOGP Well Control Incident Subcommittee believes that this incident description contains sufficient lessons to share with the industry. We further encourage the recipients of this mail to share it further within their organization.

The well was cleaned out using coiled tubing pumping inhibited water and nitrogen.

E-line was run and perforations made.

Coiled tubing was used to stimulate the well using acid. Acid was then bullheaded into the formation and allowed to soak.

Nitrogen lift initiated from below perforations using coiled tubing.

Coil tubing began POOH while continuing to lift with nitrogen.

With the coiled tubing 400' from surface the coiled tubing parted, a 30' section of degraded coil was ejected and uncontrolled nitrogen / well flow ensued until the well was shut-in ~11 minutes later using the coiled tubing pipe and blind rams.

What Went Wrong?:

- People - lack of information / interpretation / understanding / communication: pre-job planning did not identify multiple inhibition scenarios due to live well conditions or extreme corrosion hazard. Lab analysis determined a large volume of unspent acid, in combination with well gas (H2S and CO2) resulted in exponential increase in sour corrosion rates.

- Equipment - corrosion / erosion of coiled tubing (external): prolonged exposure of coiled tubing to production environment in combination with unspent acid. Coiled tubing material not compatible with both acid treatment and turbulent production well gas environment.

- Systems - work procedure issue: procedure contained steps and terminology that were not clear or were not followed: coiled tubing should not have been across perforations when nitrogen lifting due to inhibitor ineffectiveness when disrupted by turbulent flow of spent/unspent acid and well gas. Incident response plan was not tailored to high H2S situation.

Corrective Actions and Recommendations:

- Implement specific physical corrosion testing for all future coiled tubing acid jobs (specific coil, specific acid, specific inhibitors, specific application procedure / contact time / specific well conditions) to target acceptable corrosion rates during stimulation and flowback operations.

- Reduce exposure of coiled tubing to production environment / turbulent flow and visually inspect and determine remaining wall thickness after each usage.

- Emphasize expectations with pre-job design / procedural discipline / adherence to processes / job turnover / advanced planning with vendors with team members.

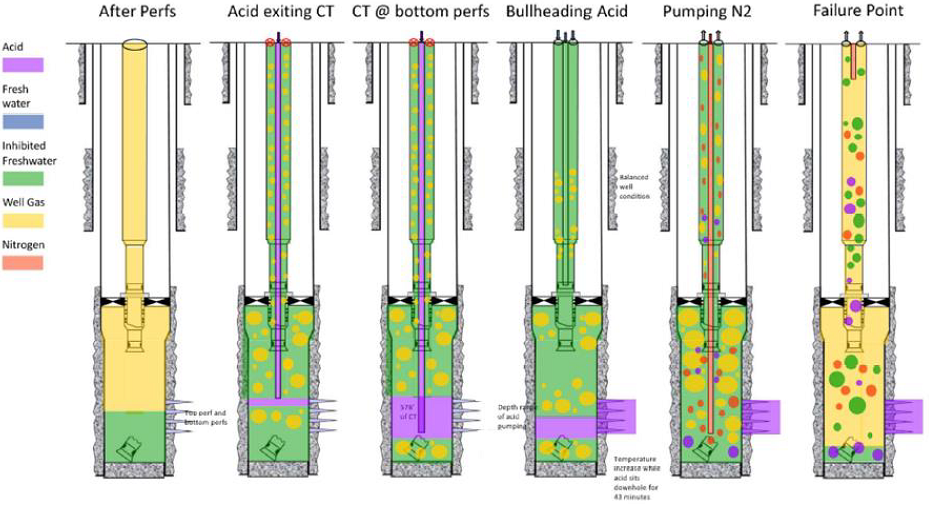

Figure 1: Sequence of events depiction

Coil exposure to production environment depicted, emphasis on coil BHA and adjacent coil within turbulent production environment while lifting with N2

Figure 2: Coil analysis

Image shows quality coil versus coil which was nearest the BHA (300') and coil further up the well (350') to emphasize the corrosive result of coil in turbulent production environment

safety alert number: 333

IOGP Well Control Incident Lesson Sharing http://safetyzone.iogp.org/

Disclaimer

Whilst every effort has been made to ensure the accuracy of the information contained in this publication, neither the IOGP nor any of its members past present or future warrants its accuracy or will, regardless of its or their negligence, assume liability for any foreseeable or unforeseeable use made thereof, which liability is hereby excluded. Consequently, such use is at the recipient's own risk on the basis that any use by the recipient constitutes agreement to the terms of this disclaimer. The recipient is obliged to inform any subsequent recipient of such terms.

This document may provide guidance supplemental to the requirements of local legislation. Nothing herein, however, is intended to replace, amend, supersede or otherwise depart from such requirements. In the event of any conflict or contradiction between the provisions of this document and local legislation, applicable laws shall prevail.