Chemical Reaction Results in Exothermic Ignition of Resin at Surface

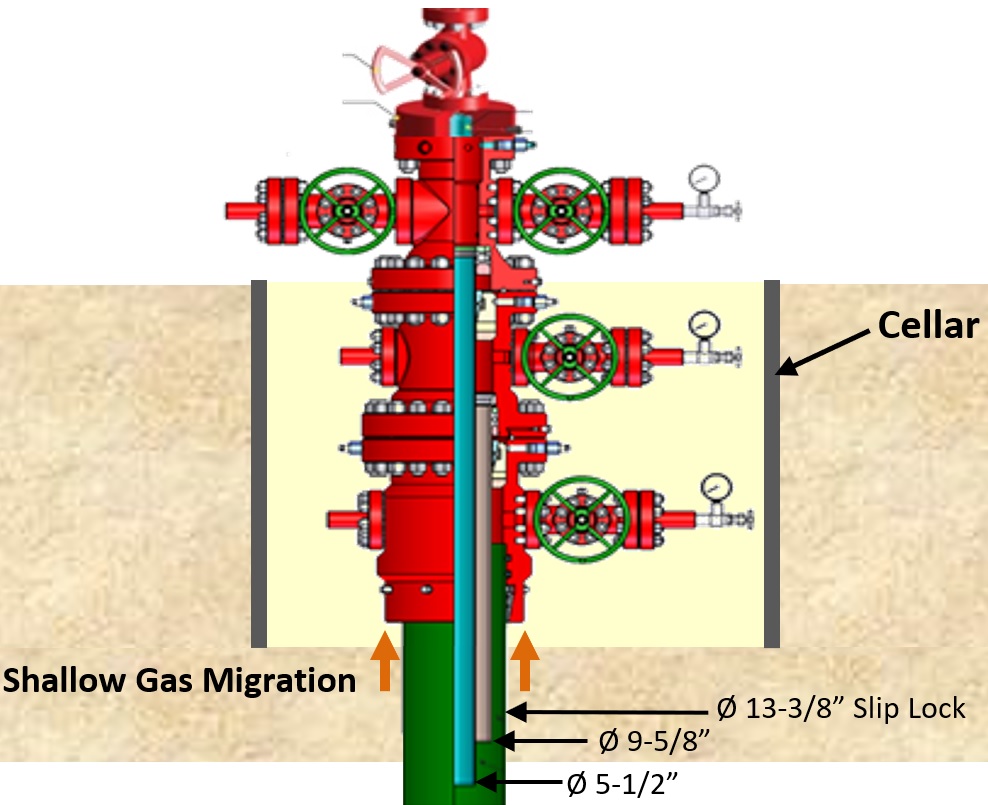

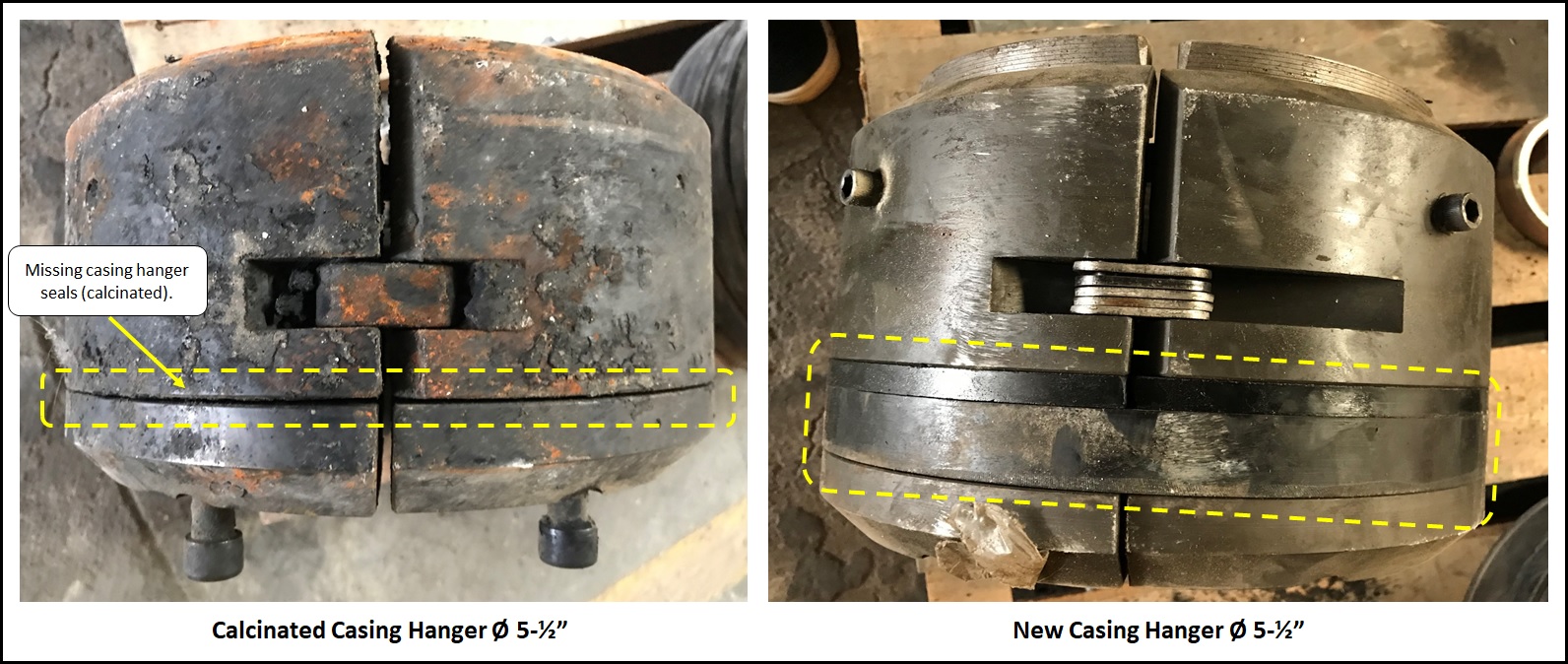

After cementing the production casing and release of the Drilling Rig on a land based operation, shallow gas migration was detected at cellar level behind Ø 13-3/8" conductor pipe. Pumping cement was ruled out due to the gas migration effect during the cement transition process. Therefore, a resin was identified as the best solution to block shallow gas migration and seal the annulus behind the 13-3/8” conductor. During the resin hardening process, an exothermic reaction occurred followed by combustion of the resin. The wellhead casing hanger seals elastomers became calcined due to the significant heat generated. This resulted in the loss of integrity in Wellhead casing hanger seals due to resin combustion at the cellar.

The IOGP Wells Expert Committee/Well Control Incident Subcommittee believes that this incident description contains sufficient lessons to be shared with the industry. We further encourage the recipients of this mail to share it further within their organization.

Loss of integrity in Wellhead casing hanger seals due to resin combustion at the cellar.

After cementing the production casing and release of the Drilling Rig, shallow gas migration was detected at cellar level behind Ø 13-3/8" conductor pipe. Given the impossibility of pumping cement due to gas migration effect during cement setting process, a resin was identified as the best solution to block shallow gas migration and seal gas influx.

During the resin hardening process, an exothermic reaction occurred followed by the resin combustion, which calcined the wellhead casing hanger seals elastomers.

The type of resin used was previously applied in downhole condition (not exposed to atmosphere).

Note: At the incident time, the well was not perforated.

What Went Wrong?:

The resin was successfully tested in lab conditions, but they did not represent the real wellsite conditions.

An excess in accelerator concentration caused an uncontrolled exothermic reaction followed by a resin volume expansion and its combustion. The volume of resin used and cellar´s geometry also contributed to the combustion process.

The resin combustion was generated by three processes, which occurred in the following order:

- Pyrolysis (Endothermic reaction, requires heat): Decomposition of the resin because of heat in an environment without oxygen (or with a very low concentration), generating solids and combustible gases.

- Latent Combustion (Exothermic reaction, releases heat): Combustion without the presence of flames. Its speed of propagation is slow.

- Rapid Combustion (Exothermic reaction, releases heat): It differs from latent combustion by generating flames and by having a much higher speed of propagation.

Corrective Actions and Recommendations:

- Establish a QA&QC protocol between Operator and Service Company for validation of new products / applications to remedy loss of well barriers integrity.

- For shallow gas wells:

- Use of gas blocking additive in the cement slurry.

- Ensure cement integrity (Well Barrier Element) by running a cement evaluation log in surface casing before drilling next section.

Figure 1: Wellhead and Cellar schematic showing shallow gas migration.

Figure 2: Resin volume expansion.

Figure 3: Wellhead state after resin combustion was extinguished.

Figure 4: Production casing hanger calcinated after resin combustion (left) and new casing hanger as reference (right).

Figure 5: Wellhead state after replacement of damage equipment.

safety alert number: 327

IOGP Well Control Incident Lesson Sharing http://safetyzone.iogp.org/

Disclaimer

Whilst every effort has been made to ensure the accuracy of the information contained in this publication, neither the IOGP nor any of its members past present or future warrants its accuracy or will, regardless of its or their negligence, assume liability for any foreseeable or unforeseeable use made thereof, which liability is hereby excluded. Consequently, such use is at the recipient's own risk on the basis that any use by the recipient constitutes agreement to the terms of this disclaimer. The recipient is obliged to inform any subsequent recipient of such terms.

This document may provide guidance supplemental to the requirements of local legislation. Nothing herein, however, is intended to replace, amend, supersede or otherwise depart from such requirements. In the event of any conflict or contradiction between the provisions of this document and local legislation, applicable laws shall prevail.