Well kick due to liner top seal failure

After several attempts and a dedicated leak detection run, the 7” and 5” x 4-1/2” liner were inflow tested successfully to max difference of +10 bar.

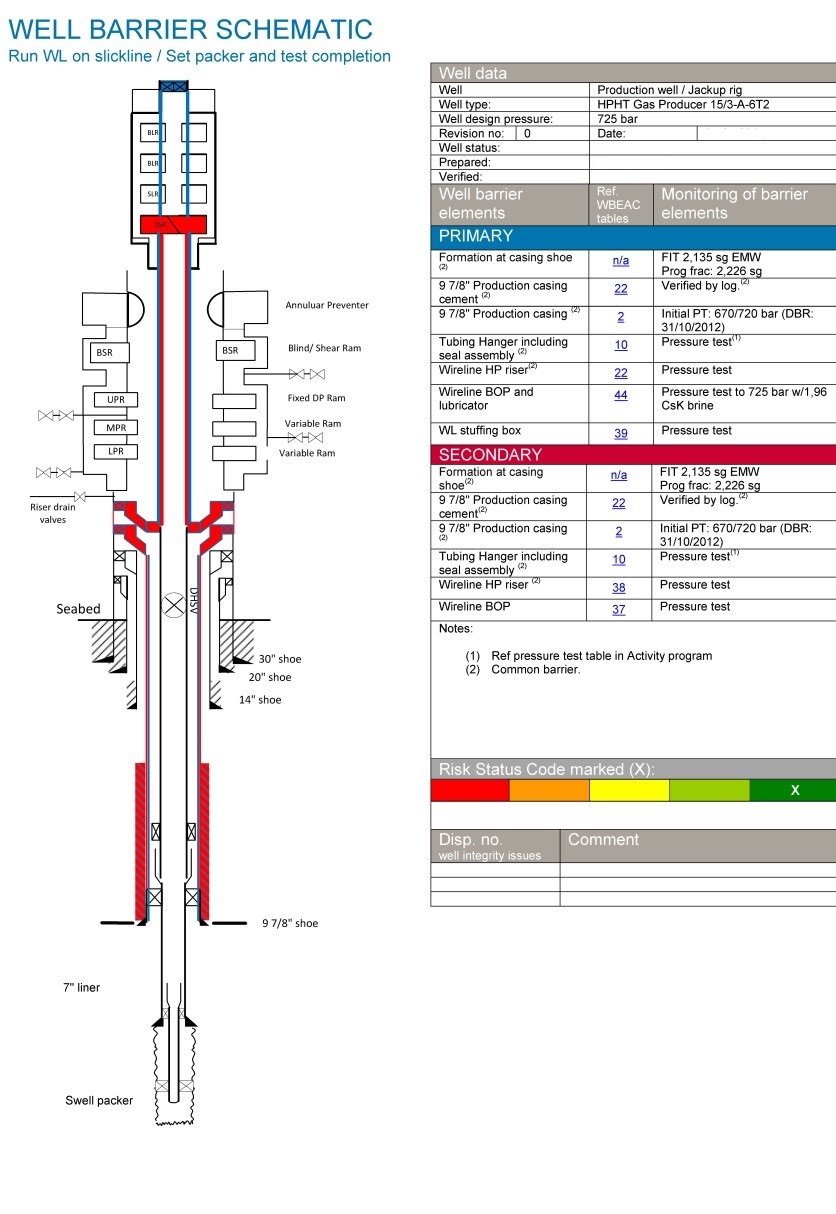

Ran completion in heavy brine and displaced well to packer fluid (underbalanced).

Rigged up wireline pressure control equipment to install plug and prong in tubing tailpipe. While RIH with the plug on WL, a sudden pressure increase was observed in the well. Pressure increased to 125 bar on the tubing side.

Attempted to bleed off pressure, but pressure increased to 125 bar immediately.

Continued operation to install plug, pressure up tubing and set production packer.

Performed pump and bleed operation to remove gas from A-annulus. The general gas alarm was triggered during his operation due to losing the liquid seal on the poorboy degasser.

Continued pump and bleed operation until no pressure on tubing and A-annulus side, and the tubing and A-annulus were tested successfully.

What Went Wrong?:

Failure of the 5" liner hanger and 5" tie-back packer.

Corrective Actions and Recommendations:

Difficult to bleed out gas in a controlled way due to sensitive choke and no pressure readings from poorboy degasser.

When performing pump and bleed operations, line up to pump down one line and take returns in a different line to optimize the operation.

Consider adequacy of the testing of the 5" liner hanger.

safety alert number: 267

IOGP Well Control Incident Lesson Sharing http://safetyzone.iogp.org/

Disclaimer

Whilst every effort has been made to ensure the accuracy of the information contained in this publication, neither the IOGP nor any of its members past present or future warrants its accuracy or will, regardless of its or their negligence, assume liability for any foreseeable or unforeseeable use made thereof, which liability is hereby excluded. Consequently, such use is at the recipient's own risk on the basis that any use by the recipient constitutes agreement to the terms of this disclaimer. The recipient is obliged to inform any subsequent recipient of such terms.

This document may provide guidance supplemental to the requirements of local legislation. Nothing herein, however, is intended to replace, amend, supersede or otherwise depart from such requirements. In the event of any conflict or contradiction between the provisions of this document and local legislation, applicable laws shall prevail.