Drilling break observed while drilling 12 ¼” hole section. Increased flow observed after the drilling break.

While drilling the 12-1/4” hole section at 3134m MD, there was a positive drilling break observed with an ROP increase from 14m/hr to 45m/hr. In addition, there was an increase in flow return right after the drilling break. The well was immediately shut-in on the annular BOP, with the HCR choke valve being opened. Pressures were taken with the following being recorded: SIDPP was 230psi and the SICP was 300psi. There was a total gain of 6bbls during the event. Well killing operations were performed using 14.3ppg KWM.

What Went Wrong?:

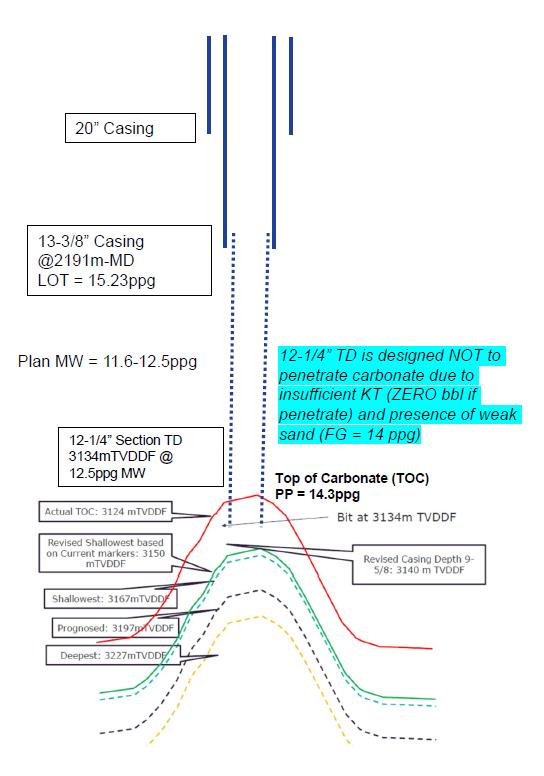

- There was an unplanned penetration into Top of Carbonate (TOC) in the 12 ¼” hole section.

- There was was a lack of correlatable formation markers (for the TOC) prior to the reservoir penetration in the offsets. Also, there were poor sand markers above the TOC which were not continuous throughout the offset wells.

- Lack of indicator or changes in drilling parameters while drilling the first 10 metres (after TOC penetration), i.e. ROP, WOB, Torque, etc..

- There was a requirement to set casing as close as possible the TOC without scratching the top to minimize shale exposure in next hole section.

- The well was not designed for TOC penetration in 12-1/4” hole section.

- The GR-Resistivity sensor was located 13m behind the bit which was way too far back.

Corrective Actions and Recommendations:

- Immediate interim measure (post incident) is to increase uncertainty window for the TOC prognosis if the plan is to stop drilling. Also, ensure to control ROP before penetrating the TOC at least 100 m above the shallowest prognosed TOC.

- Ensure to have detailed control ROP procedures in future drilling programs.

- Verify the TOC prediction using multiple velocity models and selecting the shallowest prognosed depth.

- Use a RSS with near bit gamma ray that increases the sensitivity of lithology reading to less than 5m behind the bit before encountering TOC.

- Evaluate technology such as the lookahead VSP or seismic-while-drilling in aiding TOC prediction while drilling.

- Isolate weak formation (sand with FG lower than the carbonate PP) in previous casing prior to drilling into HP carbonate.

- Ensure to maintain adequate barite, cement and chemical on the rig that is sufficient to kill the well based on KMW of HP carbonate.

Figure 1: Well schematic with location of plan and actual top of carbonate

safety alert number: 338

IOGP Well Control Incident Lesson Sharing http://safetyzone.iogp.org/

Disclaimer

Whilst every effort has been made to ensure the accuracy of the information contained in this publication, neither the IOGP nor any of its members past present or future warrants its accuracy or will, regardless of its or their negligence, assume liability for any foreseeable or unforeseeable use made thereof, which liability is hereby excluded. Consequently, such use is at the recipient's own risk on the basis that any use by the recipient constitutes agreement to the terms of this disclaimer. The recipient is obliged to inform any subsequent recipient of such terms.

This document may provide guidance supplemental to the requirements of local legislation. Nothing herein, however, is intended to replace, amend, supersede or otherwise depart from such requirements. In the event of any conflict or contradiction between the provisions of this document and local legislation, applicable laws shall prevail.