Wrong circulating volume calculation leads to gas in drilling riser

Prior to the incident, 9-5/8" casing had been set and the horizontal productive section was drilled to TD. The well was suspended for 27 days with 2 independent barriers prior to running the screen completion.

The plan when re-entering involved standard well control measures to manage any entrained gas in a controlled manner. But the entrained gas entered the riser before the BOP was closed, in preparation for circulating the last 25% of the drilling fluid through the choke. Rapid gas expansion occurred in the riser causing a mud overflow at the rig floor and shaker room.

In response, the tourpusher immediately shut in the annular and prepared to close the diverter if necessary. The floorhand exited the drill floor and the shaker hand exited the shaker room when their personal gas monitor alarmed. The ballast control operator contacted the drill floor and notified them of gas alarms.

What Went Wrong?:

Gas entered the riser due to a mistake on the annular shut-in timing, being too late to capture the last 25% of the fluid volume and circulate through the choke. This timing error resulted from misinterpreting the bottoms up volume to be bit to BOP volume in the written work instruction. The volumes to pump, detailed by the work instruction were not verified independently. Volumetric calculations for the planned circulation were conducted only by the person who had written the work instruction. Appropriate precautions were not exercised which would have ensured the fluids in contact with the reservoir were properly circulated out and de-gassed through the mud gas separator.

Corrective Actions and Recommendations:

All work instruction calculations should be subject to verification at the rig and work instructions should use simple schematics to clarify fluid volumes.

Following long suspension periods or when significant trip gas is suspected, the bottoms up practice should include stopping part way out of the hole to conduct a flow check for expanding gas, recognizing that this may give a false negative if the gas has not reached a bubble point or the volume is very small.

Re-entry into exposed reservoirs, following a long suspension, should exercise extreme caution until all fluids that have contacted the reservoir have been removed from the wellbore.

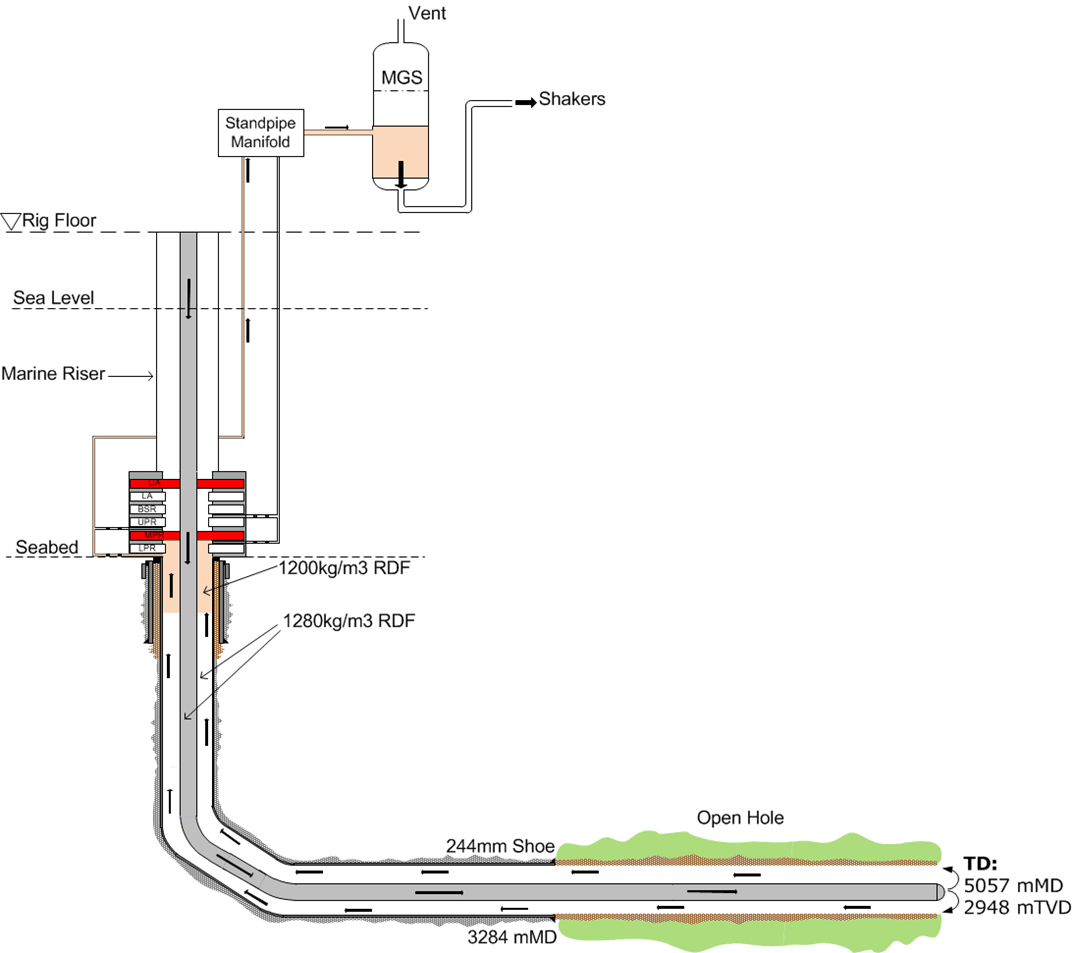

Figure 1 – Planned approach when circulating the last 1/3 in the open hole

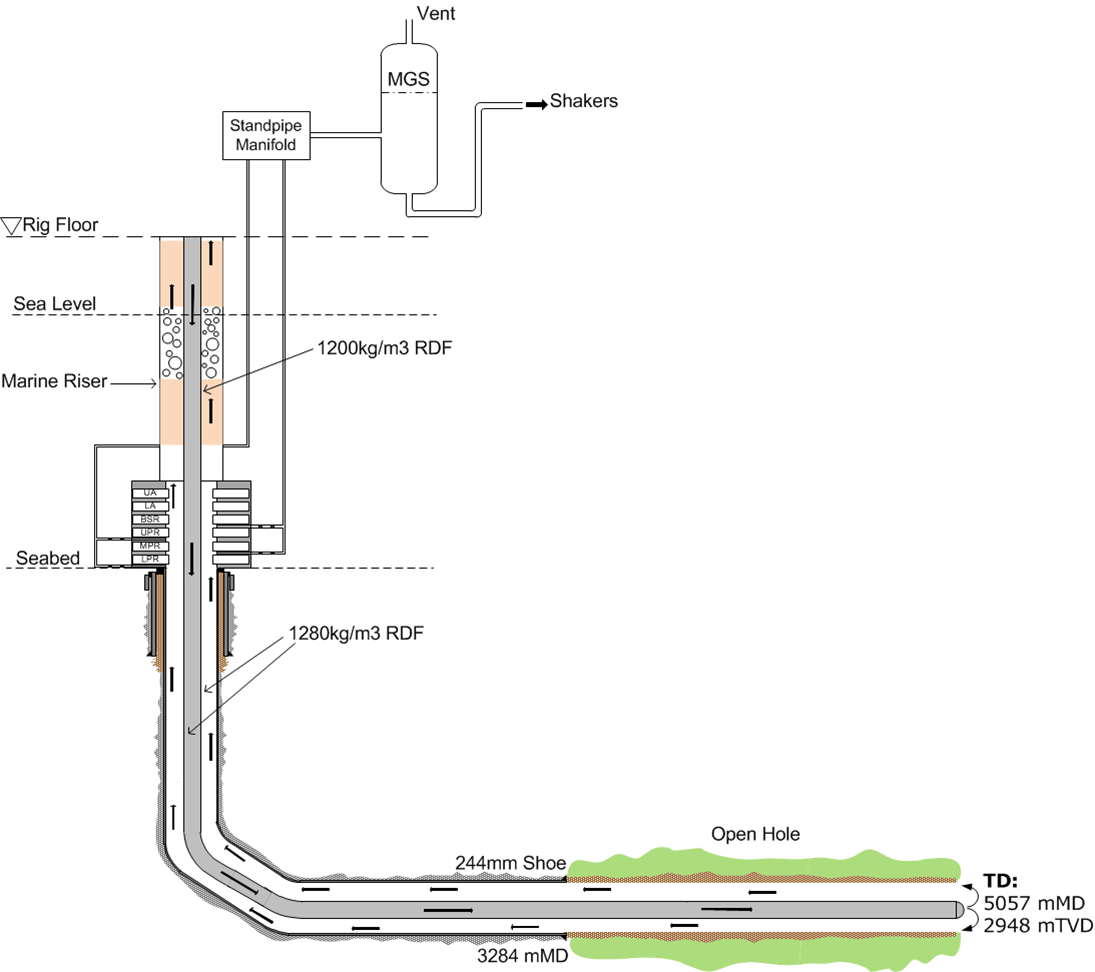

Figure 2 – What was actually executed when circulating the last 1/3 in the open hole.

safety alert number: 279

IOGP Well Control Incident Lesson Sharing http://safetyzone.iogp.org/

Disclaimer

Whilst every effort has been made to ensure the accuracy of the information contained in this publication, neither the IOGP nor any of its members past present or future warrants its accuracy or will, regardless of its or their negligence, assume liability for any foreseeable or unforeseeable use made thereof, which liability is hereby excluded. Consequently, such use is at the recipient's own risk on the basis that any use by the recipient constitutes agreement to the terms of this disclaimer. The recipient is obliged to inform any subsequent recipient of such terms.

This document may provide guidance supplemental to the requirements of local legislation. Nothing herein, however, is intended to replace, amend, supersede or otherwise depart from such requirements. In the event of any conflict or contradiction between the provisions of this document and local legislation, applicable laws shall prevail.