<<< Back to Results

Printable version

|

|

Pipe fall from skids resulting in 2 fatalities - Investigation Lessons Summary

|

Country: --- |

Location: ONSHORE |

Incident Date: 2 May 2016 Time: 18:00 |

Type of Activity: Construction, commissioning, decommissioning |

Cause: Struck by |

Function: Construction |

|

What happened?: Pipe fall from skids resulting in 2 fatalities of Contractor employees. On 2 May, 2016, at approximately 16:00 Gulf Standard Time, two employees received fatal injuries when a section of 36 inch gas export line they were working under or near fell off

the approximately 2 ft high temporary wooden supports (skid stacks) and crushed them. The two employees, a grinder and a welder, were completing a construction weld repair at the north-eastern-most weld joint of a c.120 meter curved section of the export pipeline.

Figure 1

Figure 2

Figure 3

|

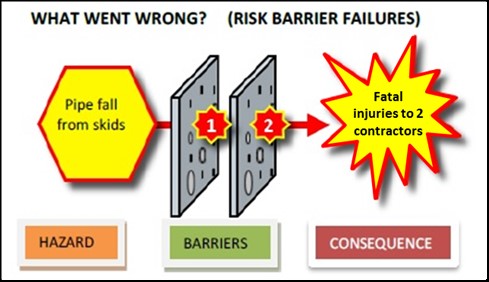

What Went Wrong?: The work permit system in place was rigorously applied to the known risks, but there was a lack of awareness of:

- The hazard presented by temporarily suspended pipes, which constituted a dynamic load / dropped object hazard.

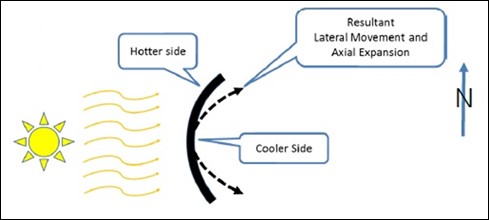

- The hazard of thermal expansion, differential heating, and residual pre-stress forces contributing to the lateral movement of curved pipe segments.

|

Corrective Actions and Recommendations:

CAUSAL ANALYSIS

- The curved pipeline section elongated and deflected due to thermal expansion, which in combination with other forces, such as pre-stress, resulted in the incident end of the pipe moving inwards relative to the radius of curvature of the pipe, by a distance

exceeding the width of the northeast end skid stack, and falling to the ground.

- The lateral movement of the curved pipeline section was initially restrained by friction between the pipe and the skid stacks and potentially by wedging of the installed chocks. As stored energy continued to accumulate in the curved pipeline section, the

restraining capability of the support skids / chocks was exceeded, and the stored energy was released in a rapid movement of the incident end of the pipeline towards the truck (pictured). Prior to that release, the pipeline appeared to be in the normal position

on the skids.

- The hazards revealed by this investigation (thermal expansion, differential heating and pre-stress, resulting in elongation and deflection of long curved pipe section, as well as the broader hazard of pipelines dropping from temporary support skids) were

not appropriately recognized.

SUMMARY OF LOCAL ACTIONS

- Develop design and monitoring methods and procedures to reduce the probability of unplanned fall of temporarily elevated pipeline sections caused by movement. Ensure supports are large enough to accommodate the worst possible movement and do not use chocks

to constrain / restrain the lateral movement of curved pipe, but rather predict and accommodate for such movement.

- Identify those tasks that place individuals at risk of injury caused by movement / falling of the pipeline and ensure that a secondary barrier is in place.

- To review all current temporary pipeline supports across the project (e.g. wooden, skidding and sand berm supports) to assess suitability, stability and margin against axial and lateral pipe loading.

KEY LEARNINGS TO SHARE

- Recognize that suspended pipelines represent dropped object (working underneath) and stored energy (working alongside) risks, and fully consider these risks in associated job hazard analyses and risk mitigations.

- While conducting risk assessments, in addition to focusing on obvious hazards of main work activities, ensure rigour in identifying less obvious and latent risks that could materialise under certain conditions.

- If activities are to be undertaken in accordance with industry custom and practice, make sure these requirements are clearly communicated to those undertaking the task, fully understood by all stakeholders (including permitting authorities) and clearly

documented.

|

Visit this link for an animation of the incident, lessons learned and corrective actions and recommendations.

https://youtu.be/0SQqSmHGMyo. |

|

|

Safety Alert number: 277

IOGP Safety Alerts http://safetyzone.iogp.org/ |

Disclaimer

Whilst every effort has been made to ensure the accuracy of the information contained in this publication, neither the IOGP nor any of its members past present or future warrants its accuracy or will, regardless of its or their negligence, assume liability for any foreseeable or unforeseeable use made thereof, which liability is hereby excluded. Consequently, such use is at the recipient's own risk on the basis that any use by the recipient constitutes agreement to the terms of this disclaimer. The recipient is obliged to inform any subsequent recipient of such terms.

This document may provide guidance supplemental to the requirements of local legislation. Nothing herein, however, is intended to replace, amend, supersede or otherwise depart from such requirements. In the event of any conflict or contradiction between the provisions of this document and local legislation, applicable laws shall prevail.

|